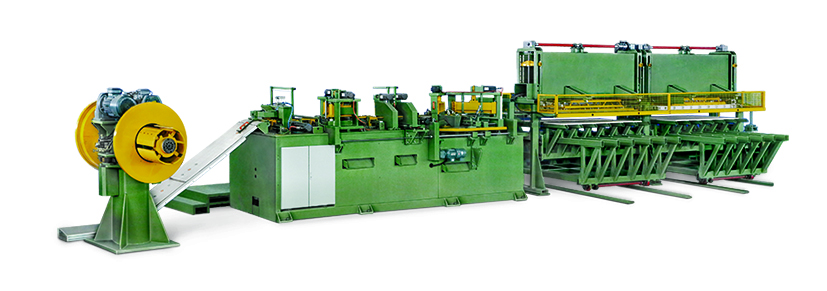

SR.HJ-400B Cut-to-Length Line (for Transformer core) Characteristics:

1. The line realize material feeding at high accurate fixed length, through precise length measuring device – American Rockwell (Allen-Bradley) AC servo system and the most advanced motion control system in the world, to ensure the shearing precision.

2. Adopt visual multicolour HMI with Chinese language display, operators can easy finish operations such as slice shape option, parameter modification etc.

3.Computer carry out length compensation, quickly adjust sheared length.

4.Adoption double head decoiler to enhance productivity; Hold tightly by hydraulic and rotation control by electrical.

5. Punching machine adopt rolling linear bearing to guide, Shearing machine adopt line guide rail (PMI heavy duty model) to guide.

6.Both Punching machine and Shearing machine adopt hard alloy as cutter material, cutter life 1 million times per grinding.

7.Guiding of whole line for width adjustment is automatic. Guiding system for sheet material is transversal centrosymmetric retractable structures (centralized positioning); Width adjustment system is centralized driving, automatic width adjustment through encoder feeding back and close loop technology, and meanwhile increase additional manual fine adjustment function, position indicator display and observation function.

8.Adopt hard alloy as rail material, average service cycle is 8 ~ 10 years; All rail system adopt linear guide way, and ball screw as transmission.

9.Punching machine (gap) employ servo unit control for lateral movement, can automatically finish shearing of marching type folding of core.

10.BUS control system:

Adoption of Ethernet loop BUS control technology: unique PLC of American Rockwell(Allen-Bradley), servo drivers for whole line, frequency convertor etc, to realize full digitalization and intelligent control, both reliability and control precision have large improvement. Most sensors, solenoid valve connected to near DP bus, control signs and power supply are supplied by DP bus. Using of DP bus, greatly reduce quantity of electrical cables, and then improve the reliability of equipments, reduce maintenance costs, improve the fault diagnosis efficiency.

Thickness of sheet (mm):0.23 - 0.35

Width of sheet (mm):40 - 440

Length of sheet (mm):250 - 2500

Feeding speed (m/min):0 - 200

Accuracy of cutting length (mm):±0.10

Accuracy of cutting angle (o):±0.02

Shear burr error (mm):<0.02

Punch mould working life (万次 10000 times):>20 (刃磨一次 per grinding)

Shear working life (万次 10000 times):>100 (刃磨一次 per grinding)

Open roll telescoping scope (mm):Φ460 - 520

Installed capacity (KW):28

Compressed air consumption (cbm/min):1.5

NANTONG SIRUI ENGINEERING CO., LTD.

Tel: +86 513 87273218

Fax: +86 513 87275595

E-mail: info@springmake.com

Add.: No. 86, Xiaokang Road, Dongchen Town, Rugao City, Jiangsu Province, China